Blog

3PL vs. 4PL Logistics: Definition and Comparison

Written by:

Megan Marsh

We’re laying down the law on the often confused — and sometimes debated — “PL” terminology. What is a 3PL, how does it differ from a 4PL, and which one is right for your company?

It can be tough to decide whether you need a 3PL versus a 4PL logistics provider to optimize your supply chain. Making the wrong choice can cost millions of dollars and negatively impact your customer service levels — so you’ll want to get it right.

In this article, I’ll share my best definitions, compare the differences between 3PL and 4PL, and explain how these solutions can support your unique supply chain strategy.

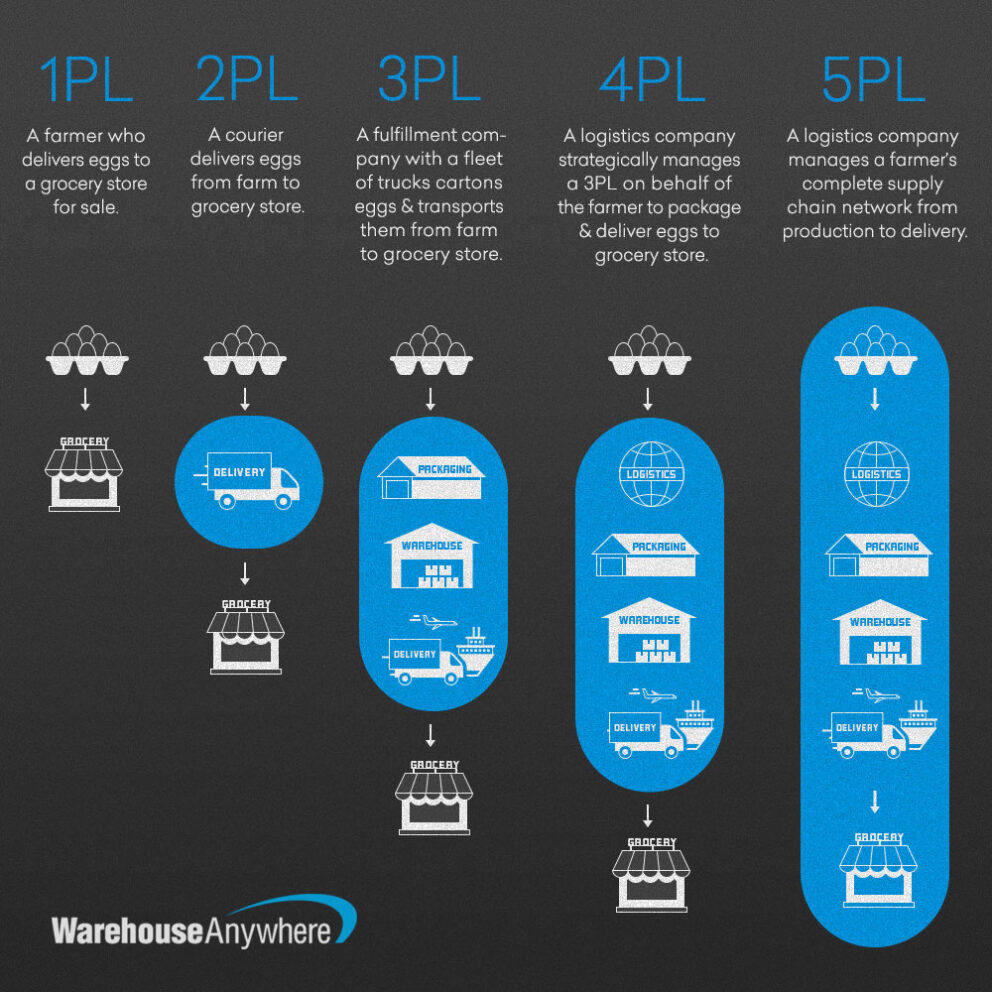

1PL, 2PL, 3PL, 4PL, 5PL Definitions

1PL – First-Party Logistics

An enterprise that sends goods or products from one location to another is a 1PL. For example, a local farm that transports eggs directly to a grocery store for sale is a 1PL.

2PL – Second-Party Logistics

An enterprise that owns assets such as vehicles or planes to transport products from one location to another is a 2PL. That same local farm might hire a 2PL to transport their eggs from the farm to the grocery store.

3PL – Third-Party Logistics

In a 3PL model, an enterprise maintains management oversight, but outsources operations of transportation and logistics to a provider who may subcontract out some or all of the execution. Additional services may be performed such as crating, boxing and packaging to add value to the supply chain. In our farm-to-grocery store example, a 3PL may be responsible for packing the eggs in cartons in addition to moving the eggs from the farm to the grocery store.

4PL – Fourth-Party Logistics

In a 4PL model, an enterprise outsources management of logistics activities as well as the execution across the supply chain. The 4PL provider typically offers more strategic insight and management over the enterprise’s supply chain. A manufacturer will use a 4PL to essentially outsource its entire logistics operations. In this case, the 4PL may manage the communication with the farmer to produce more eggs as the grocery store’s inventory decreases.

5PL – Fifth-Party Logistics

A 5PL provider supplies innovative logistics solutions and develops an optimum supply chain network. 5PL providers seek to gain efficiencies and increased value from the beginning of the supply chain to the end through the use of technology like blockchain, robotics, automation, Bluetooth beacons and Radio Frequency Identification (RFID) devices.

As we progress through the spectrum of logistics models from 1PL to 5PL, it’s clear that more and more of the logistics function is in the hands of the provider rather than the enterprise itself. The most common models now are 3PL and 4PL and we’ll look at how each one can help solve supply chain challenges.

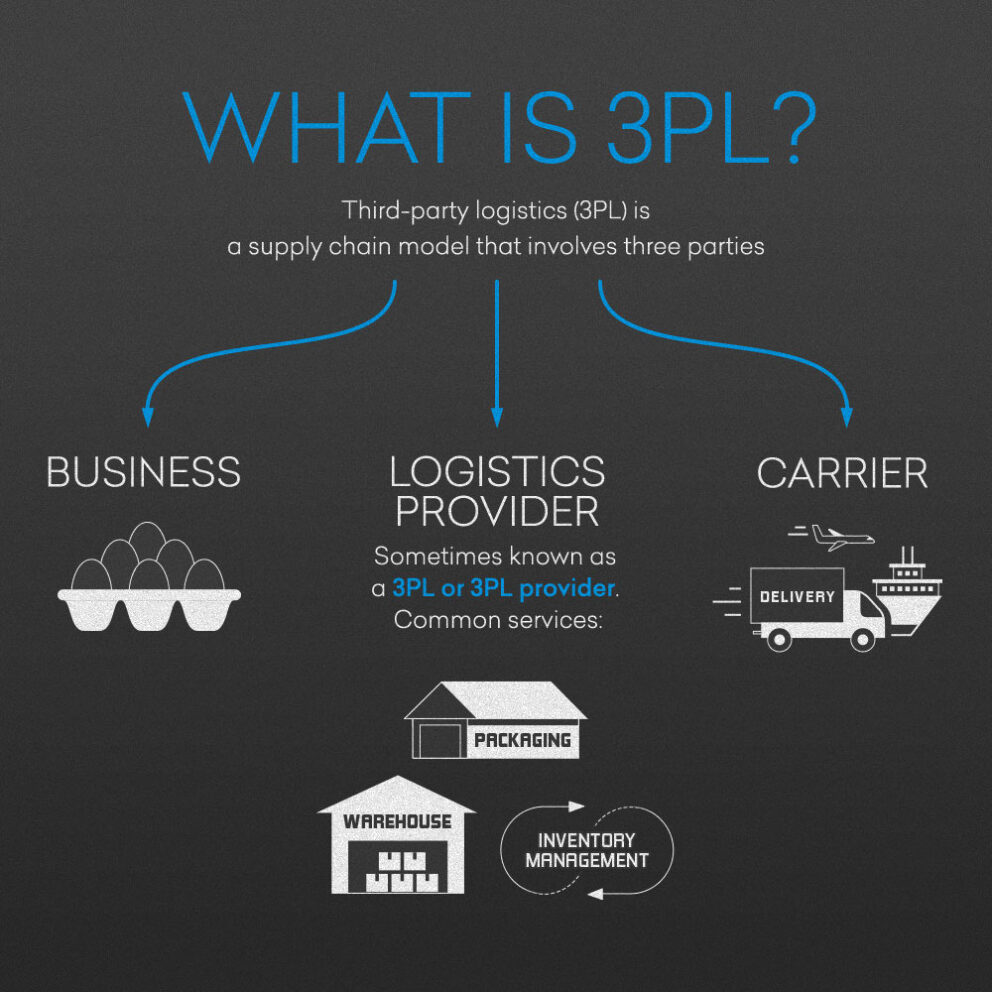

What is a Third-Party Logistics Provider?

The term “third-party logistics provider,” or 3PL, has been around since the 1970s. It simply means that a third party is involved in a company’s logistics operations, in addition to the shipper/receiver and the carrier.

A 3PL does not take ownership of (or title to) the products being shipped. This third party comes into play as an intermediary or manager between the other two parties.

The first 3PLs were intermodal marketing companies that accepted loads from shippers and tendered them to railroads, becoming a third party in the contract between shippers and carriers, according to the Council of Supply Chain Management Professionals (CSCMP) glossary. Today, any company that offers some form of logistics services for hire is known as a 3PL. This includes facilitating the movement of parts and materials from suppliers to manufacturers, as well as finished products from manufacturers to distributors and retailers.

A 3PL may or may not have its own assets, such as trucks and warehouses. In some cases, the role of 3PL and broker overlap, but typically a broker is used to engage trucking capacity for a specific shipment. A 3PL may act as a broker or use brokers to move clients’ freight.

Most 3PLs offer a bundle of integrated supply chain services, including:

- Transportation

- Warehousing

- Cross-docking

- Inventory management

- Packaging

- Freight forwarding

A 3PL can scale and customize services to meet customers’ needs based on their strategic requirements to move, store, and fulfill products and materials. Companies turn to 3PLs when their supply chain becomes too complex to manage internally. For example, a company may grow through mergers and acquisitions, so a supply chain that was manageable at one time outgrows the in-house capability.

The 3PL offers experience gained from working for multiple clients across many different industries. They also offer technology solutions — in some cases, proprietary tools — such as transportation and warehouse management systems beyond what the shipper could afford to invest in independently. Long-term relationships with carriers can result in better pricing and service during periods when capacity may come at a premium. The economy of scale can lower prices on everything from packing tape to ocean shipping rates.

Advantages of 3PL

A 3PL will offer innovative strategies to transform your supply chain into a cost-effective, responsive model. Consider what we’re doing at Warehouse Anywhere as an example. In contrast to the traditional single distribution center (DC) model, we have pioneered and perfected forward-deployed inventory management. The common hub-and-spoke DC model is not able to keep up with the pace of business, with large inventories and infrequent truck service. We’ve developed the forward-deployed model for warehousing and distribution that uses a larger number of smaller locations to move products closer to the customer. This decentralized, hyper-connected model provides the responsiveness needed to meet customers’ expectations for timely delivery.

No matter if you’re direct-to-consumer or in a service-level agreement situation, customers expect overnight delivery, or as close to it as possible. The Warehouse Anywhere system can optimize your inventory per location to ensure stock is on hand in areas of highest demand. You will save on transportation and logistics expenses while improving customer service.

Disadvantages of 3PL

While the 3PL model has been successful for decades, there are some things to consider. Perhaps the most significant caveat is the lack of direct oversight and control. After all, a 3PL is an outsourced service provider. That means some activities will take place outside of your direct supervision. Ensuring quality control and customer service requires an extra level of diligence. If a 3PL fails to deliver on a customer’s expectation, the customer will blame your company, not the 3PL.

Another issue is the degree of dependency a 3PL can create. When you outsource a significant segment of your business, it can be difficult to switch providers or take the operations in-house if pricing or service levels no longer meet expectations.

3PL by Industry

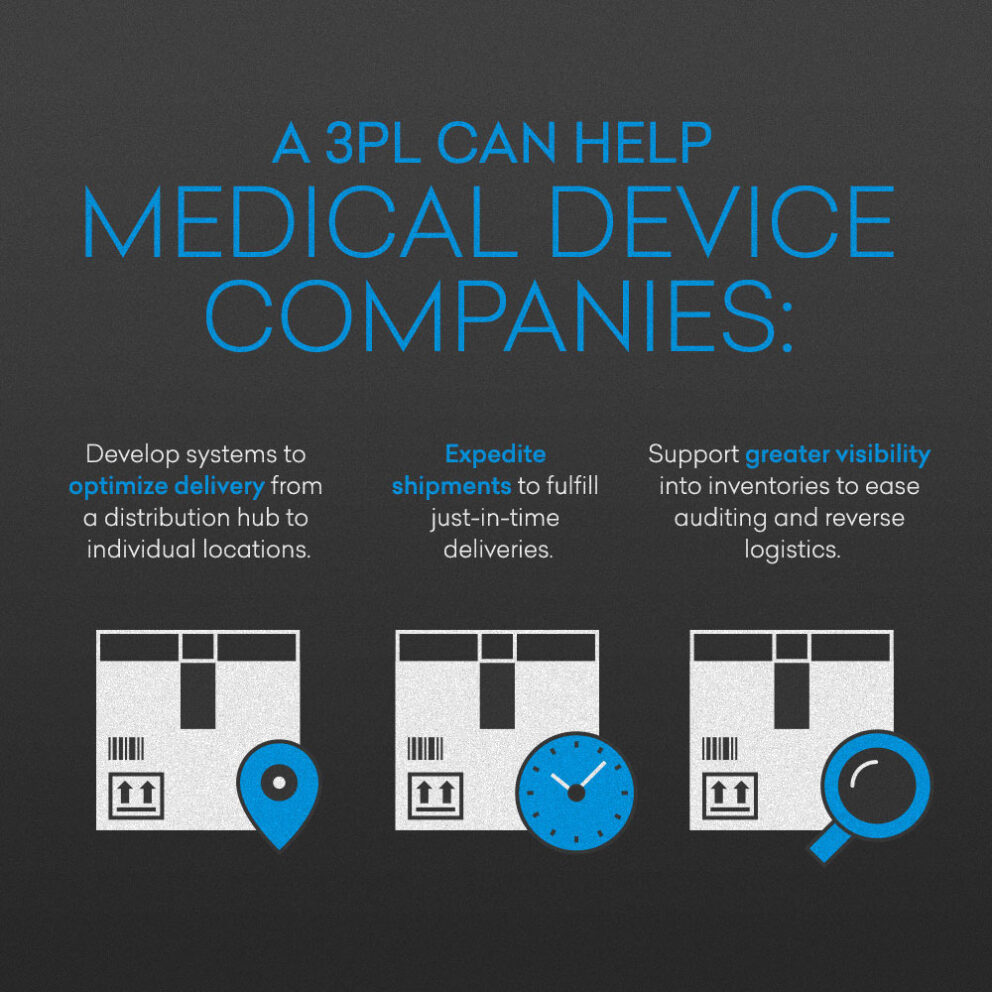

3PLs for Medical Devices

For industries with complex supply chain requirements, 3PLs deliver solutions that turn challenges into competitive advantages.

For the medical device industry, visibility and value-added delivery processes are top priorities. To meet regulatory requirements, devices must be tracked throughout every step of the process with a verifiable chain of custody. This capability requires complex technology solutions that can track inventory across multiple locations and carriers to ensure individual devices can be tracked and traced at a moment’s notice.

Medical device shippers rely on 3PLs for services that go well beyond dropping off boxes on the dock. Clients are looking for delivery to the end-user department, on-site inventorying, returns and repairs and other small but vital steps in serving customers.

A 3PL can help a medical device company develop systems to optimize delivery from a distribution hub to individual locations. Rather than delivering half a dozen items in many shipments, the 3PL can develop the visibility to consolidate deliveries to reduce costs significantly. 3PLs can manage expedited shipments to fulfill just-in-time delivery for high-value items, such as knee implants. Greater visibility into inventories and reverse logistics improves ease of auditing, reducing the need for physical auditing.

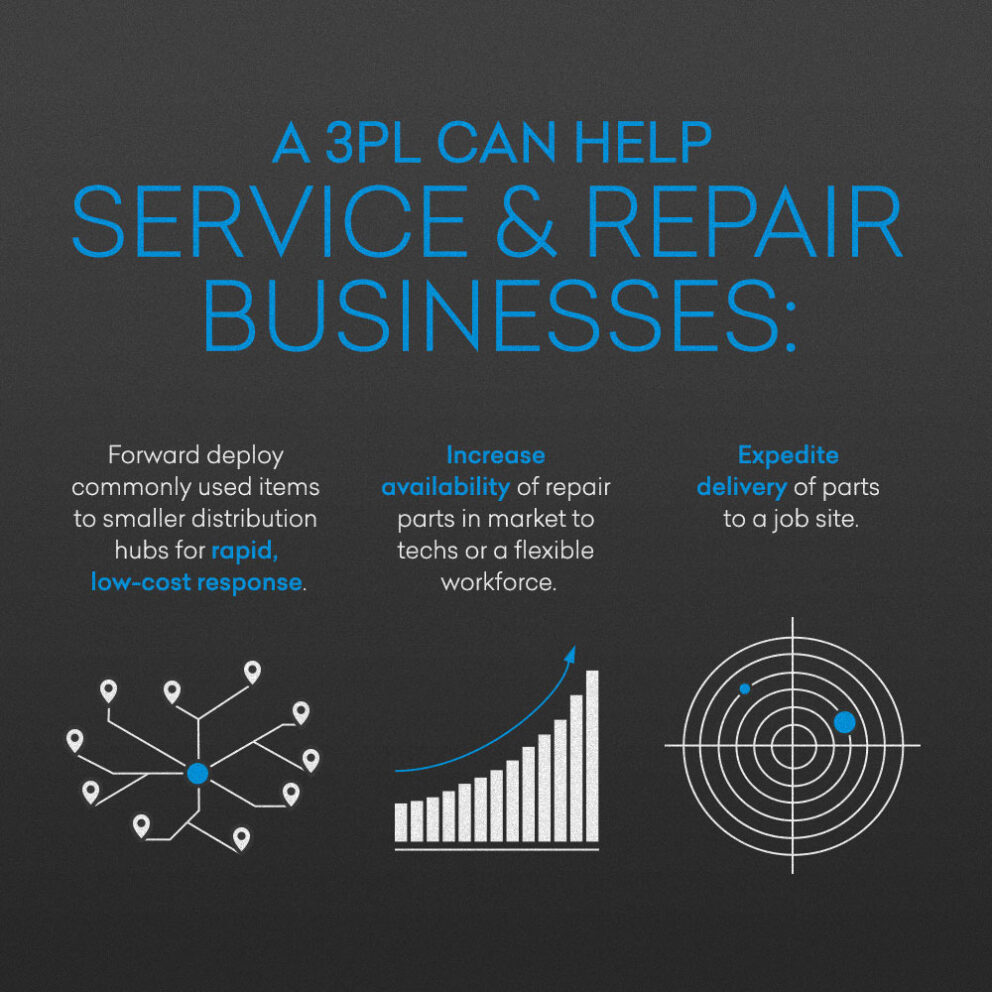

3PLs for Field Services

Companies with extensive field service operations, no matter if they’re strictly internal or offer services to clients, will benefit from 3PL partnerships. A field service environment is different than a manufacturing situation and requires unique solutions. Meeting service level agreement (SLA) expectation is crucial to customer satisfaction, and a well-managed forward deployment program can ensure standards are met or exceeded.

To meet these high expectations, a 3PL can forward deploy commonly used items in smaller distribution hubs for rapid, lower cost response. The 3PL can develop a database of the most often ordered items and ensure inventory is managed to meet ongoing demand. Having the right part available when the service technician makes the initial call will contribute to a high level of customer satisfaction. The service tech can stop at the hub to pick up parts or place an order for expedited delivery to the job site.

3PLs for Retail

Thanks to the “Amazon effect,” customers have come to expect merchandise to be readily available online or in-store. After all, if you can receive practically anything from Amazon in two days or less, customers don’t understand why they can’t receive goods from other shippers in the same time frame. A 3PL can develop a strategy to improve supply chain discipline to better compete with Amazon on shipping times and fulfillment accuracy.

What is a Fourth-Party Logistics Provider?

A fourth-party logistics provider, or 4PL, represents a higher level of supply chain management for the customer. The 4PL gives its clients a “control tower” view of their supply chains, overseeing the mix of warehouses, shipping companies, freight forwarders and agents.

The goal is to have the 4PL act as the single interface between all aspects of the supply chain and the client organization. Consulting firm Accenture originally copyrighted the term in the mid-1990s, but it has since fallen into generic use.

In some cases, a 4PL may be established as a joint venture or long-term contract between a primary client and multiple partners, often to manage logistics for specific locations or lines of business. The structure of a 4PL can vary, as there may be a 4PL component within a larger 3PL relationship. A 4PL is a form of business process outsourcing, similar to contracting out human resources or financial functions.

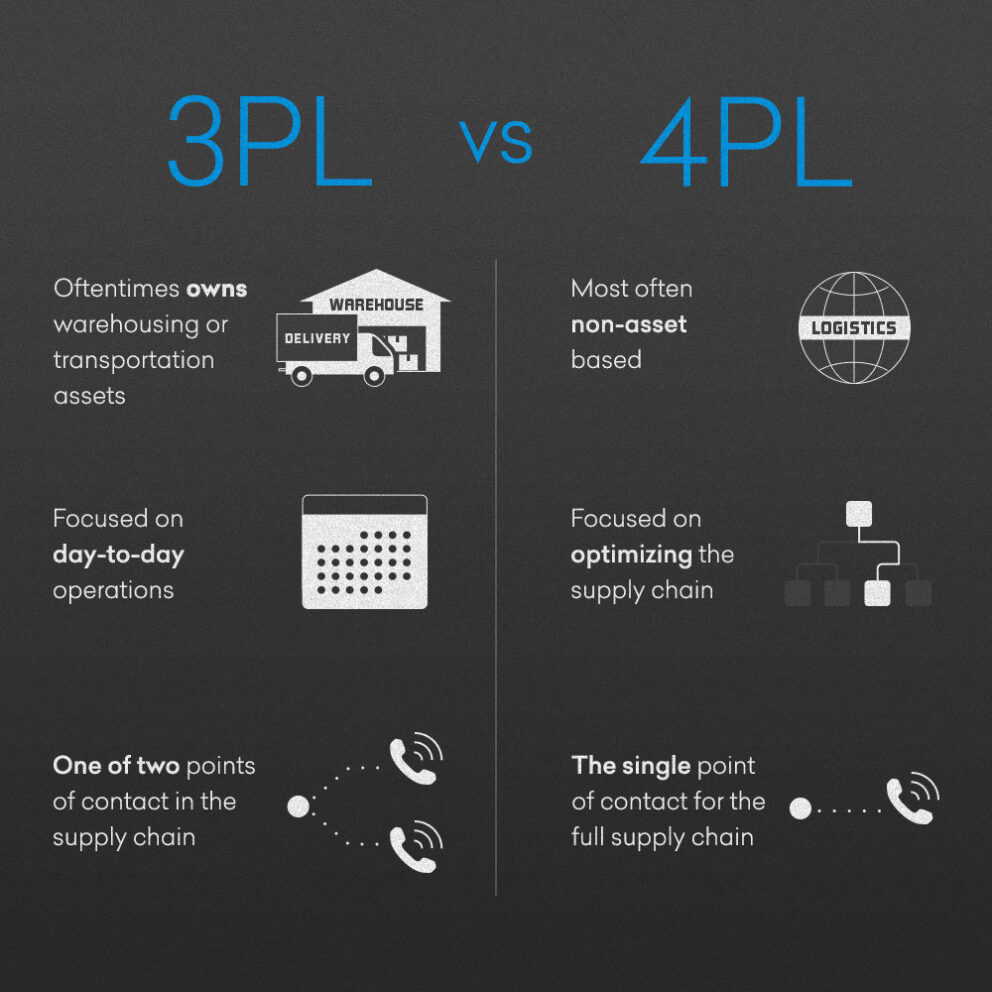

What’s the Difference Between 3PL and 4PL Logistics?

Typically, the 4PL does not own transportation or warehouse assets. Instead, it coordinates those aspects of the supply chain with vendors. The 4PL may coordinate activities of other 3PLs that handle various aspects of the supply chain. The 4PL functions at the integration and optimization level, while a 3PL may be more focused on day-to-day operations. A 4PL also may be known as a Lead Logistics Partner (LLP), according to the CSCMP.

The primary advantage of a 4PL relationship is that it is a strategic relationship focused on providing the highest level of services for the best value, as opposed to a 3PL that may be more transaction focused. A 4PL provides a single point of contact for your supply chain. With a 3PL, there may be some aspects that you still have to manage. The 4PL should take over those processes for you, acting as the intermediary for 3PLs, carriers, warehouse vendors and other participants in your supply chain.

The 4PL relationship simplifies and streamlines the logistics function using technology for greater visibility and imposing operational discipline across many partners and suppliers. The enterprise can focus on its core competencies and rely on the 4PL partner to manage the supply chain function for maximum value. Basically, the 4PL acts as the enterprise would if the supply chain functions were managed in-house.

As companies transition their supply chain model to forward deployment or decentralized distribution, a 4PL partner can step in and manage that complexity. Retailers, in particular, are shifting toward a more nimble model to support e-commerce and omnichannel services. A 4PL can manage the multiplying number of resources that it takes to compete at that level. The days of the million-square-foot super regional DC may be over, as companies opt for shared warehouse space near major customer centers to speed up responsiveness. The 4PL can manage those relationships, as well as optimize the network to use parcel carriers or couriers to support e-commerce, rather than LTL or truckload services.

Fourth-Party Logistics Advantages

Choosing a 3PL vs. a 4PL can be a complicated decision that depends on the complexity of your supply chain and your company’s strategic goals.

A 3PL relationship works well when the organization has a solid, high-performance supply chain strategy in place and requires support to execute the plan. Working with a 3PL will typically require a high level of internal management commitment and oversight to ensure performance meets your standards. However, many day-to-day decisions are out of your hands as you count on the providers selected by the 3PL to meet your service commitments. An asset-based 3PL may focus too much on ensuring that its own assets are fully utilized at the expense of lower rates or better services from other providers. For smaller companies, a 3PL can provide an immediate level of scale that would otherwise be cost prohibitive.

A non-asset based 4PL is agnostic in choosing suppliers, concentrating on finding the best combination of value and service. Typically, a 4PL will have integrated technology offerings that deliver a high level of visibility into the supply chain for tactical and strategic analysis. Of course, internal resources are still necessary to manage the 4PL performance, but it should be a higher level of oversight than a 3PL.

Warehouse Anywhere has performed as both a 3PL and 4PL for our clients. Recently, we’ve seen great success in acting as a 4PL in managing forward-deployed inventories in a variety of vertical markets. We can localize your inventory in hundreds of U.S. cities in a very short period of time.

4PL by Industry

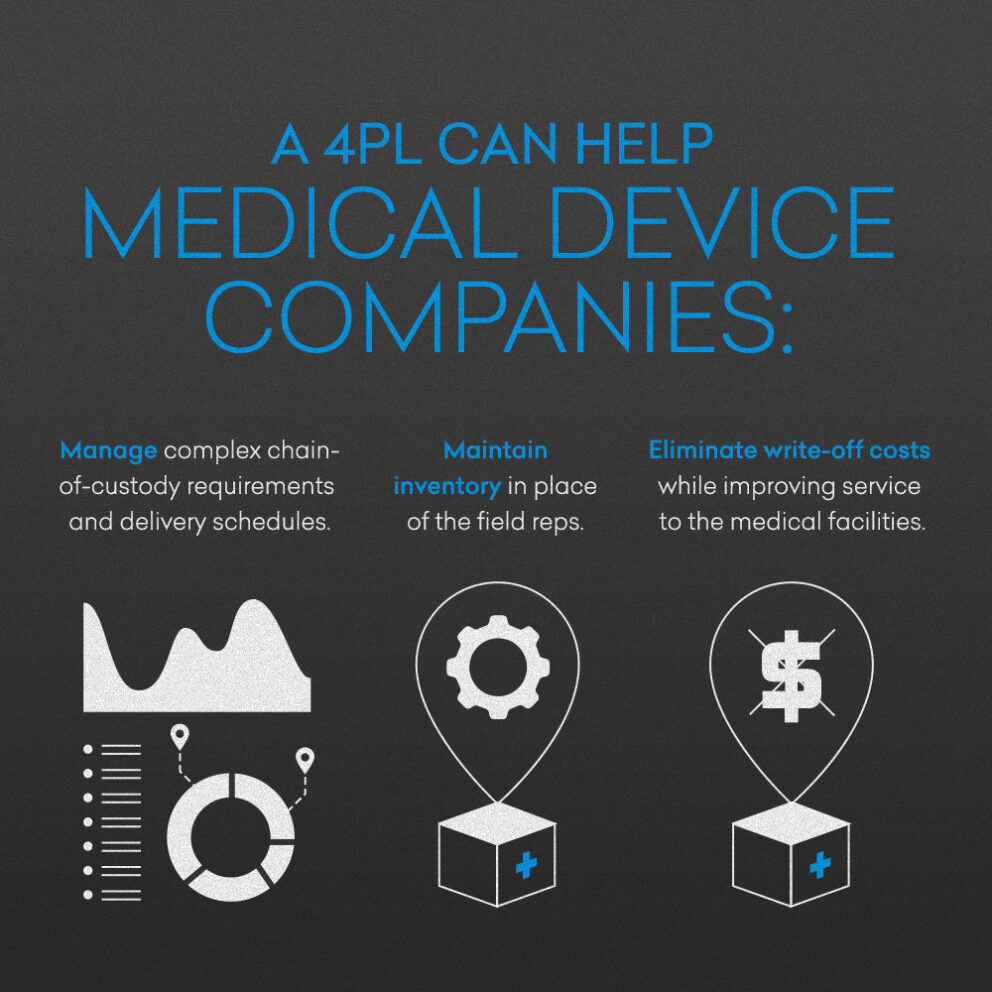

4PLs for Medical Devices

Did you know that sometimes surgeons order a medical device such as a knee replacement only after the patient has started the anesthesia process? Talk about just-in-time delivery. Surgeons may order several sizes of a product because they don’t know precisely which one they’ll need at the start of the procedure. A 4PL can manage the complex chain of custody requirements and delivery schedules to meet physician’s requirements and reduce inventory costs.

For one medical-device manufacturer Warehouse Anywhere developed a network of inventory centers to service hospitals and surgery centers. We maintain their inventory, relieving field reps of that burden and eliminating consignment costs. Since we guarantee delivery of items up to one hour prior to surgery, physicians can preschedule surgeries as well. We handle all reverse logistics and restocking of unused items.

We found in many cases physicians typically ordered more than $3.5 million worth of devices in a year, but used only about $300,000 worth. The extra cost of shipping these items to and from the hospital and DC were excessive, and consumed by the medical device company. Our solution helped eliminate inventory write-off costs while improving service to the medical facilities. Now, this medical device company sees their supply chain as a competitive advantage rather than a cost center.

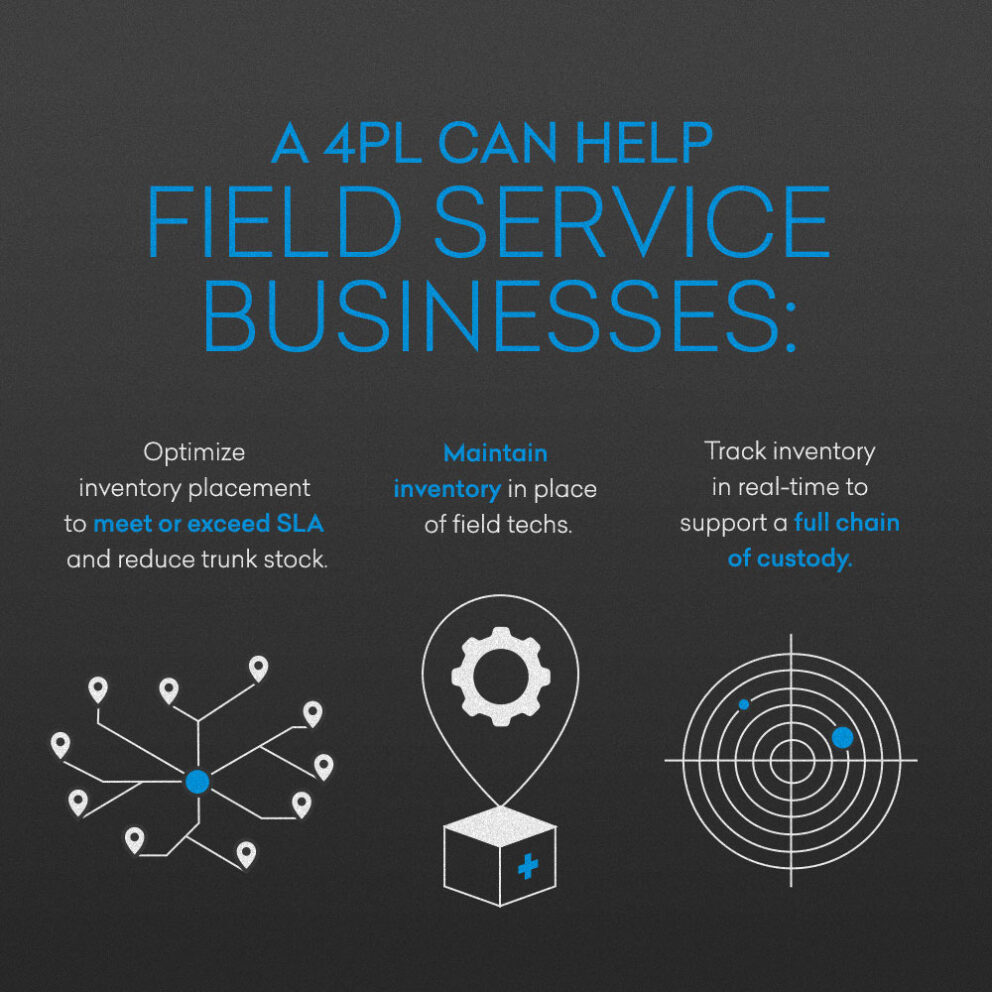

4PLs for Field Service

To serve field service and repair organizations a 4PL takes control of the supply chain including warehousing, fulfillment, transportation and technology.

The Warehouse Anywhere forward-deployed 4PL model is perfect for field service businesses because we manage all the moving parts to meet your service expectations. The process begins with a detailed analysis of parts usage based on historical data and installed customer base to determine the individual parts, quantities and locations necessary to meet anticipated demands.

The field techs don’t have to function as warehouse operators anymore. Parts location and inventories are visible to all the techs in the region, reducing the need for trunk stock.

For one field service organization supporting retail and financial services technology, Warehouse Anywhere established a decentralized warehousing model, and developed a fulfillment system to provide parts in 30 minutes or less, meeting or exceeding service level agreements. Its real-time inventory tracking and visibility support full chain of custody, 24/7 inventory availability and ERP/IT integration.

4PLs for Retail/E-Commerce

The largest e-commerce companies, like Amazon, act as their own 4PLs by owning and managing the entire supply chain. Few other companies have the resources to match that, so they turn to 4PLs for strategic management.

Over the years, many retailers have used 3PLs for transportation, warehousing and fulfillment. As e-commerce boomed, retailers often bolted on those capabilities to existing systems, creating parallel supply chains to meet in-store and online demand. As e-commerce logistics matures, it’s become apparent that an omnichannel approach is a sustainable direction to support customers, regardless of the channel from which they purpose.

A 4PL offers the strategic vision to create a new supply chain network that efficiently manages the flow of product across all platforms. A single view of inventory gives the retailer the power to allocate inventory and meet customer demand regardless of the status or location of the inventory.

Forward-deployed inventory can serve both physical locations and e-commerce fulfillment. For brick-and-mortar locations, the forward deployment supports same-day inventory replenishment as well as online order fulfillment from the same location.

With smaller store footprints, there’s no room “in the back” anymore. For a retail apparel customer, we forward deployed inventory within a five-mile radius of stores to replenish popular items within one hour.

3PL vs. 4PL – What’s Best for Your Company?

If your company is dealing with an increasingly complex supply chain and struggling to meet customer expectation for faster response, then an innovative 3PL or 4PL may be the best solution for you.

In partnering with an innovative leader, your supply chain solutions can be optimized for maximum customer value with a competitive advantage. The most successful logistics partnerships seamlessly blend the flow of products and information flow, and that’s where our technology truly enables supply chain excellence.

Whether you’re direct-to-consumer or offering service-level agreements to business-to-business partners, you know that overnight delivery (or close to it) is what your customers expect. That’s why Warehouse Anywhere is on a different level than other 3PL companies. If you are servicing a large national market, you can place fast-moving parts, materials or products in multiple fulfillment warehouse locations that are closest to your points of highest demand. This forward-deployed inventory model allows us to store your resources everywhere that you need them to be.

In addition to a distribution or fulfillment service, you’ll also have a layer of technology and expertise that a traditional 3PL warehouse doesn’t have. You will save on your transportation and logistics while also achieving excellent customer service.

To find out more about positioning your assets where you need them most, please don’t hesitate to connect with me on LinkedIn or contact us online today.

Ready to Speak to an Expert?

We’re ready to build a tech-based solution for your business.